Services

The long experience matured in the time makes D’AMBRA able to offer a qualified technical support during the design phase and/or the workmanship of the products, useful to find the best solution for the optimization of the productions.

The firm performs, on commitment of Client, the following activities: design, feasibility study and industrialization of part and/or mechanical assemblies, development of work cycles and part programs for machining CNC, finalized to the cost reduction.

The work activity usually begins with the analysis of the drawings or sketches supplied by the Client or, eventually, from the evaluation of a sample of the item to be produced.

In such case the elaboration of the sketches is performed by computer (CAD) and sent to the production departments (CAM).

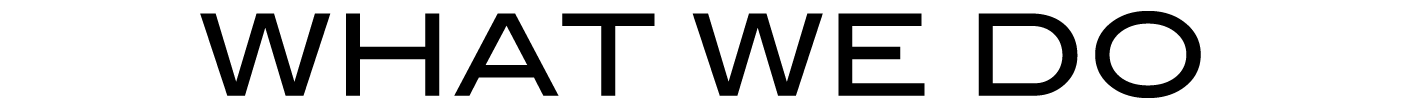

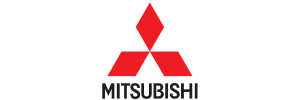

The various phases of manufacturing are carried out in the following departments: Cut, Presetting, Milling CNC (3/4/5 axes), Lathing CNC (4/5 axes), Grinder CNC (surface and round), Spark erosion CNC (EDM and EDW), Punching CNC, Bending press CNC, Cutting plates with Laser technology, testing and quality control with CMM in temperature-controlled metrology room.

During the development of the production process, great importance is given to the Quality considered by D’AMBRA as a global approach involving all the business activities. The constant improvement of its products and the continuous investments in modern productive equipments, are finalized by D’AMBRA towards the customer satisfaction that remain the main reference point of every business choice.

D’AMBRA considers the Logistic as an aspect of fundamental importance that involves the whole productive process, from the start of the work order up to when the order is filled. A rigorous management of the Logistic allows to rationalize resource and means to fulfil the lead time of the products. After the final testing, the products are properly packaged and stored.

The process concludes with the delivery of the products to the Customer.

The storage of special mechanical parts having high level of precision and delicacy and the custody of classified material (confidential or restricted) are assuredì in the firm, by special structures that guarantee the custody in conformity with the standard requirements for the industrial security.

D’AMBRA pursues, as strategic objective, the Costumer satisfaction to achieve through the continuous improvement of all its internal processes, developing and applying a total quality management program.

To reach an high level of reliability D’AMBRA has implemented a Quality System in conformity with the most important international standards, covering different aspect such as management, safety personnel and control of the impact on the environment.

D’AMBRA it is certified EN 9100:2018; UNI EN ISO 9001:2015.